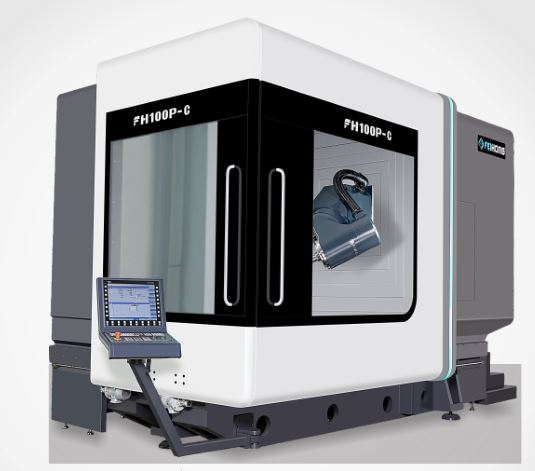

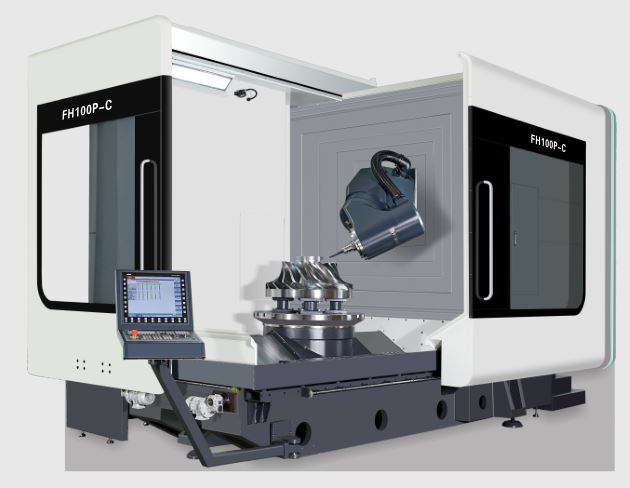

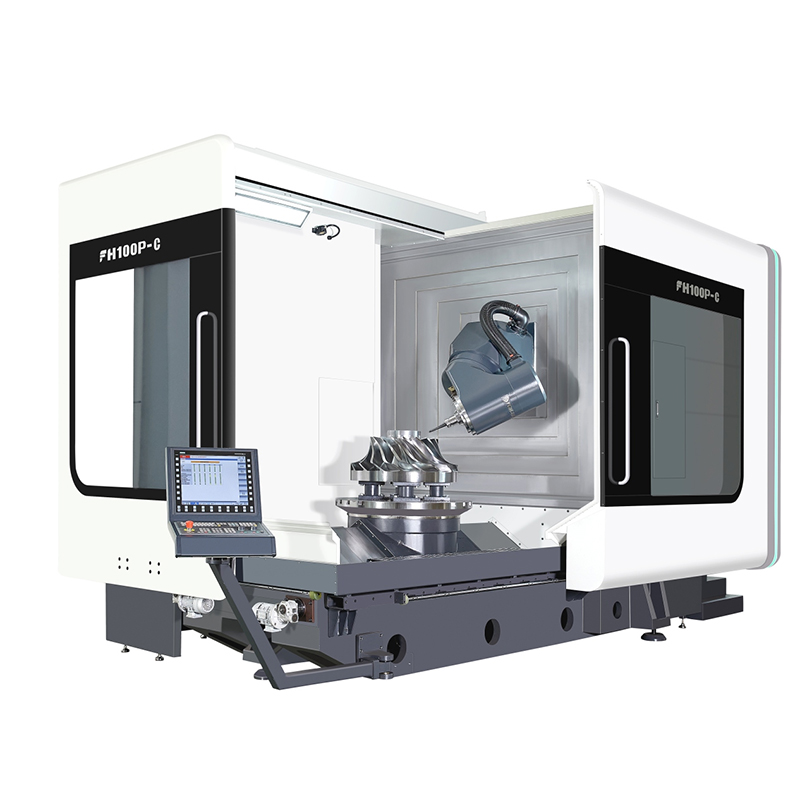

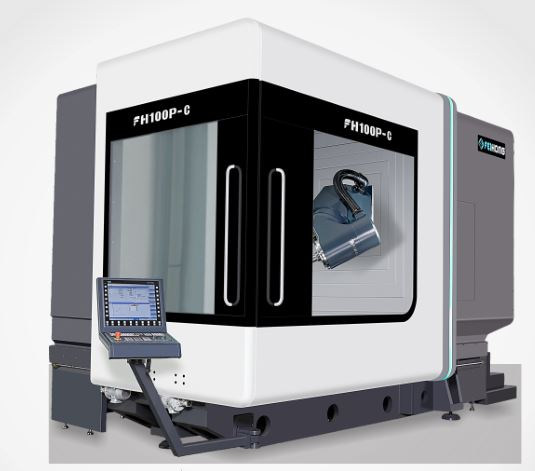

5 Axes Igbakana milling Titan 100P-C

Dopin ti ipese

Tabili iṣẹ awọn ẹya ara ẹrọ boṣewa (jọwọ tọka si iṣẹ oludari fun apakan iṣakoso ina)

1. Siemens 840DSL adarí

2. Brand Ara marun-axis olona-iṣẹ golifu ori

3. itanna spindle DGZX-24012/34B2-KFHWVJS

4. HSK-A100 40-tool irohin laifọwọyi ọpa ayipada eto

5.X/Y/Z ṣofo itutu rogodo dabaru drive

6. Awọn ifaworanhan laini rola 7 (3 fun axis X, 2 fun ipo Y/Z) —BOSCH REXROTH

7. X / Y / Z mẹta-axis ni kikun pipade-lupu opitika olori

8. Ohun elo iṣakoso iwọn otutu apoti itanna

9. Spindle kula

10. Ajija ërún sẹsẹ ẹrọ ati ki o ru iron ërún conveyor iron ërún ọkọ ayọkẹlẹ

11. Omi lati aarin ti awọn spindle, annular omi sokiri

12. Fẹ afẹfẹ ni aarin spindle, ki o si fẹ afẹfẹ ni iwọn.

13. Osupa oṣupa ori-apa marun-un ti nfẹ omi, oṣupa oṣupa si nfẹ afẹfẹ.

14. 1 iru aabo interlock fun iwaju ati ẹgbẹ ṣiṣẹ ilẹkun

15. Spindle san itutu ẹrọ.

16. Mabomire ṣiṣẹ Fuluorisenti atupa

17. Ẹrọ ibudo hydraulic

18. Renisaw OMP60 infurarẹẹdi ibere Unit

19. Renisaw lesa Ọpa Setter

20. Central si aarin laifọwọyi ono ẹrọ lubrication

21. Isẹ ẹgbẹ ninu omi ibon ati air ni wiwo

22. Ige ito itutu eto

23. Ni kikun paade aabo dì irin

24. apoti isẹ

25. Apoti itanna ti wa ni ipese pẹlu air conditioner

26. Siemens itanna handwheel

27. Ẹsẹ-ṣiṣẹ spindle ọpa Tu yipada

28. Awọn paadi ipele ipilẹ ati awọn boluti ipilẹ

29. Awọn irinṣẹ atunṣe ati awọn apoti irinṣẹ

30. Imọ Afowoyi

Paramita

| Nkan | Uni | FH100P-C |

| X axis irin ajo | mm | 1000 |

| Y axis ajo | mm | 1150 |

| Z axis irin ajo | mm | 1000 |

| Ijinna lati imu spindle lati ṣiṣẹ tabili dada | mm | 160-1160 |

| Petele milling ori | mm | 30-1030 |

| Ifunni / sare gbigbe iyara | m/min | 40 |

| Agbara ifunni | KN | 10 |

| Tabili Rotari (apa C) | ||

| Ṣiṣẹ tabili iwọn | mm | Ø1050 |

| Eru tabili ti o pọju (ọlọ) | kg | 4000 |

| Eru tabili ti o pọju (titan) | kg | 3000 |

| Rotray tabili | rpm | 45 |

| Milling / titan woking tabili (ọpa milling ati titan) | rpm | 500 |

| Igun pipin ti o kere julọ | ° | 0.001 |

| Ti won won iyipo | Nm | 1330 |

| O pọju iyipo | Nm | 2630 |

| Ori milling CNC (axis B) | ||

| Iwọn gigun (0 = Inaro/180=Ipele) | ° | -15-180 |

| Iyara gbigbe ati iyara ifunni | rpm | 103 |

| Igun pipin ti o kere julọ | ° | 0.001 |

| Ti won won iyipo | Nm | 1050 |

| O pọju iyipo | Nm | 2130 |

| Spindle (yiyi ati ọlọ) | ||

| Iyara Spindle | rpm | 10000 |

| Spindle agbara | Kw | 42/58 |

| Spindle iyipo | Nm | 215/350 |

| Spindle tapre |

| HSKA100 |

| Ijinna lati ile-iṣẹ spindle si tan ina guideway dada | mm | 1091.5 |

| Awoṣe | Ẹyọ | FH100P-C |

| Iwe irohin irinṣẹ | ||

| Ohun elo ni wiwo |

| HSKA100 |

| Ọpa irohin agbara | PCS | 40 |

| Max.tool opin / ipari / iwuwo |

| Ø135/300/12 |

| Yipada Irinṣẹ (Ọpa si) | S | 2 |

| Ẹrọ wiwọn | ||

| Iwadi infurarẹẹdi | Rensishaw OMP60 | |

| Irinṣẹ wiwa irinṣẹ ni agbegbe iṣẹ ṣiṣe | Rensishaw NC4F230 | |

| Agbara ṣiṣe | ||

| Iwọn liluho to pọju (irin Alabọde) |

| Ø50 |

| Iwọn ila opin ti o pọju (irin Alabọde) |

| M40 |

| Iwọn milling ti o pọju (irin alabọde) |

| 250 |

| Ipeye (ISO230-2 ati VDI3441) | ||

| X/Y/Z išedede ipo | mm | 0.006 |

| X/Y/Z Tun ipo deede | mm | 0.004 |

| B/C ipo išedede |

| 8" |

| B/C Tun ipo deede | 4" | |

| Eto iṣakoso |

| Siemens840D |

| Giga ẹrọ (Ẹrọ gbogbogbo) | mm | 3650 |

| Agbegbe ti a tẹdo fun ẹrọ akọkọ (L*W) | mm | 5170x3340 |

| Agbegbe ti a tẹdo fun iwe irohin irinṣẹ (L*W) | mm | 1915x1400 |

| Agbegbe ti a tẹdo fun gbigbe chirún (L * W) | mm | 3120x1065 |

| Agbegbe ti a tẹdo fun ojò omi (L*W) | mm | 1785x1355 |

| Lapapọ agbegbe ti a tẹdo lati pari ẹrọ (L*W) | mm | 6000x3750 |

| Iwọn ẹrọ | Kg | 21000 |

Ẹrọ CNColudari

| Iṣakoso System | Siemens 840DSL (moto ati wakọ) | ||

| Nọmba ti Iṣakoso àáké | 5-axis milling igbakana pẹlu titan nigbakanna (NC axis + spindle, BC axis) | ||

| Igbakana Iṣakoso ti 5 axe Igbakana milling pẹlu titan | ipo ipo | Iwọn X, Y, Z, B, C | |

| interpolation | ila gbooro | X, Y, Z, B, C aake (X, Y, Z, B, C le sanpada) | |

| aaki | X, Y, Z, B, C aake (X, Y, Z, B, C le sanpada) | ||

| Ẹka itọnisọna to kere julọ | 0.001um | ||

| kere Iṣakoso kuro | 0.1nm | ||

| Ifihan | 19 LCD | ||

| Mọto | Agbara apọju mẹta pẹlu koodu koodu pipe (ipo koodu ko padanu rara) | ||

| Ita ibaraẹnisọrọ iṣẹ | Àjọlò ati RS232C ni wiwo | ||

| Ipo iṣẹ | MDI, Aifọwọyi, Afowoyi, Ọwọ, Oti (idi), REPOS | ||

| eto eto | Olootu ede ISO lori ayelujara | ||

| O pọju agbara ipamọ siseto PLC | 2048KB | ||

| Interpolation iṣẹ | Awọn laini taara, awọn iyika nipasẹ ati nipasẹ awọn aaye aarin, awọn spirals, awọn ipele ti o dara, awọn eto iyara giga, ati bẹbẹ lọ. | ||

| Nọmba awọn aiṣedeede irinṣẹ | 512 awọn ẹgbẹ | ||

| Imugo kẹkẹ ọwọ | 0.1 / 0.01 / 0.001mm | ||

| Eto ti o kere julọ ati awọn ẹya gbigbe | 1um/X,Y,Z | ||

| fifipamọ data | Data iranti kii yoo sọnu nigba ti agbara ba wa ni pipa | ||

| kikọ sii oṣuwọn | 0%-150% | ||

| Iyara siwaju titobi | 0%-100% | ||

| Input ati o wu ni wiwo | Ethernet ati RS232C ni wiwo, CF kaadi, USB ipamọ afẹyinti | ||

| ede ifihan | Chinese ati English | ||

Standard iṣeto ni opoiye

| No | Orukọ ẹya ẹrọ | ẹyọkan | Qty |

| 1 | ẹsẹ Iṣakoso yipada | ṣeto | 1 |

| 2 | Eefun ti clamping siseto | ṣeto | 1 |

| 3 | Ohun elo Lubrication Aarin | ṣeto | 1 |

| 4 | itutu eto | ṣeto | 1 |

| 5 | atupa ṣiṣẹ | ṣeto | 1 |

| 6 | Imọlẹ awọ mẹta | ṣeto | 1 |

| 7 | petele Afara | Awọn PC | 1 |

| 8 | Awọn atunṣe ọpa ẹrọ | ṣeto | 1 |

| 9 | Standard Ọpa Package | ṣeto | 1 |

| 10 | aabo enu titiipa | ṣeto | 1 |

| 11 | ipilẹ kit | ṣeto | 1 |

| 12 | Fi sori ẹrọ ohun elo atunṣe | ṣeto | 1 |

| 13 | Kosemi kia kia ati spindle olona-ojuami aye | ṣeto | 1 |

| 14 | Dabaru conveyor ati ki o laifọwọyi ërún yiyọ ẹrọ | ṣeto | 1 |

| 15 | Standard eefun ti eto | ṣeto | 1 |

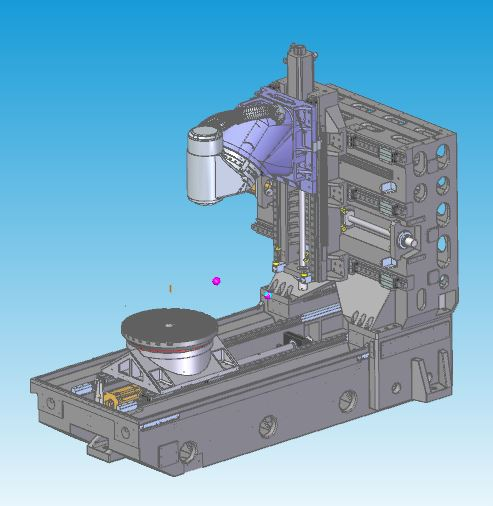

Design Awọn ẹya ara ẹrọ | Ti o dara ju Mechanical Waya Simẹnti Analysis Design

Ni kikun apoti iru thermosymmetric simẹnti be, lilo Meehanna ite ga-ite simẹnti irin

Tempering ati itọju ti ogbo adayeba lati yọkuro aapọn inu

Gbigbọn igbohunsafẹfẹ adayeba ti igbekale ṣe imukuro aapọn ṣiṣe ohun elo

Apẹrẹ ọwọn rigidity giga-agbegbe nla pẹlu ogiri ni kikun, imunadoko imunadoko ati aimi ati iṣedede agbara

Mẹta-ipo ṣofo itutu dabaru drive

Ori milling CNC (axis B)

Design Awọn ẹya ara ẹrọ

Itumọ ti DD motor odo gbigbe pq ko si apẹrẹ ẹhin

Ga isare abuda

Akoko ti o kuru ju laarin aaye imu ọpa ti spindle ati aaye atilẹyin igbekale mọ rigidity ti o pọju ti gige.

Awọn biarin YRT ti o tobi julọ n pọ si rigidity

Ti ni ipese pẹlu eto wiwọn koodu rotari giga-giga HEIDENHAIN, iṣakoso lupu pipade ni kikun lati rii daju pe deede to dara julọ

Spindle ati B-axis eto itutu agbaiye apẹrẹ lati dinku gbigbe ooru

Tabili Rotari (apa C)

Design Awọn ẹya ara ẹrọ

Itumọ ti DD motor odo gbigbe pq ko si apẹrẹ ẹhin

Ga isare ati deceleration esi abuda

Awọn biarin YRT ti o tobi julọ n pọ si rigidity

Yiwọn awakọ ti o tobi, ipo ati sisẹ pẹlu ipo tabili ati ẹrọ dimole

Pade awọn iwulo processing meji ti milling ati titan-titan, dinku mimu mimu iṣẹ ṣiṣẹ ati ilọsiwaju deede ọja

Ti ni ipese pẹlu eto wiwọn koodu rotari giga-giga HEIDENHAIN, iṣakoso lupu pipade ni kikun lati rii daju pe deede to dara julọ

Apẹrẹ eto itutu lati dinku gbigbe ooru

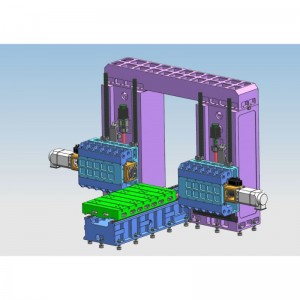

Oluṣeto irinṣẹ gbigbe

Design Awọn ẹya ara ẹrọ

Ni ipese pẹlu Ransishaw NC4F230 oluṣeto ohun elo laser ti kii ṣe olubasọrọ fun pipe ti o ga julọ

Eto irinṣẹ aifọwọyi lori ẹrọ, imudojuiwọn aifọwọyi ti isanpada ọpa

Ẹrọ eto ọpa le gbe soke ati silẹ lati ṣafipamọ aaye ti dada processing

Apẹrẹ irin ti a fi edidi ni kikun ṣe aabo olupilẹṣẹ ọpa lati inu omi ati awọn ifilọlẹ irin lakoko sisẹ

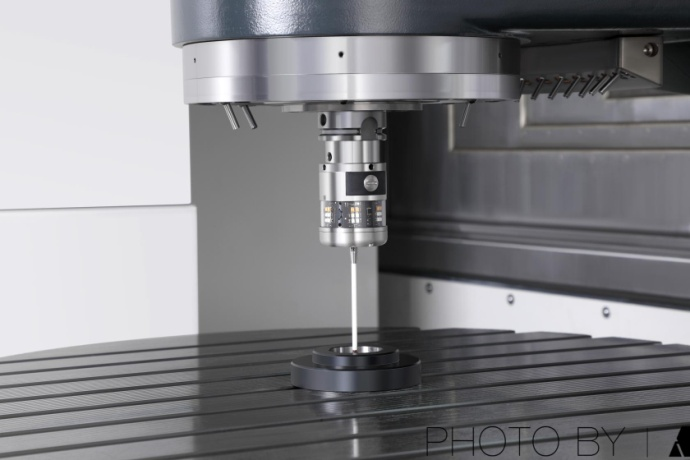

Iwadi infurarẹẹdi

Design Awọn ẹya ara ẹrọ

Ni ipese pẹlu Ransishaw OMP60 opitika ifọwọkan ibere

Titete iṣẹ iṣẹ ẹrọ lori ẹrọ ati ayewo iwọn, dinku awọn aṣiṣe ayewo afọwọṣe, ilọsiwaju deede ọja ati ṣiṣe ṣiṣe

90% awọn ifowopamọ ni akoko iranlọwọ ẹrọ