Marun-ipo Gantry Machining Center GF Series

Awọn ẹya ara ẹrọ

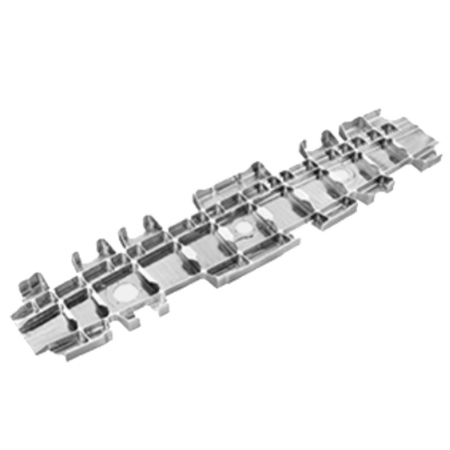

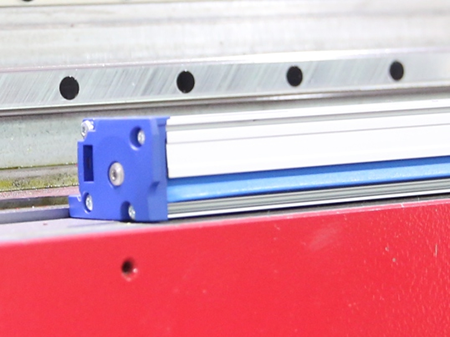

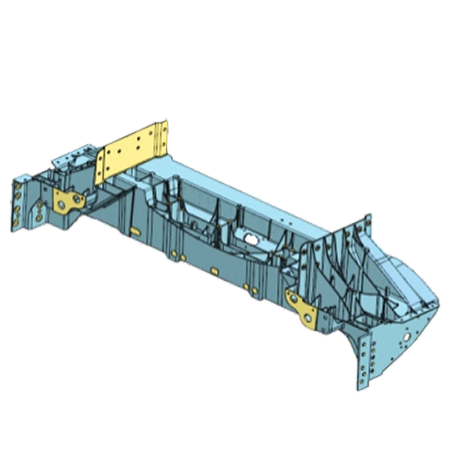

Tilted Design Of The X-apakan

Giga Syeed fifi sori ẹrọ ti o yatọ si awọn afowodimu ila ila ila X-axis ṣe idaniloju rigidity giga ati mọ iyara-giga ati ipo pipe-giga

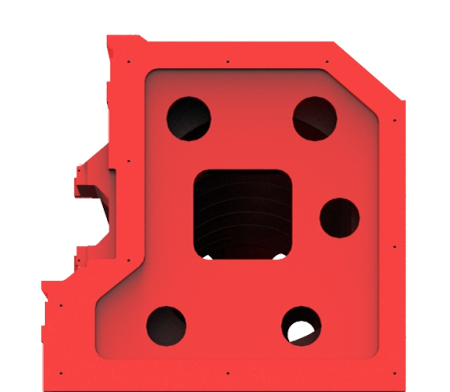

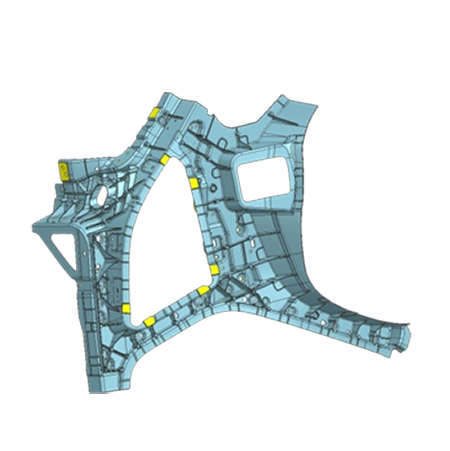

Pataki U-sókèSadieDapẹrẹ

A ṣe apẹrẹ ori pẹlu ori ori lile ti o ga, eyiti o jẹ dimole nipasẹ gàárì U-sókè nipasẹ awọn irin-ajo itọsọna ni ẹgbẹ mejeeji lati rii daju pe rigidity giga ti ẹrọ itẹsiwaju Z-axis

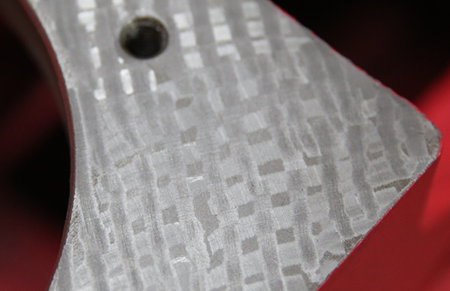

AwọnJororoSurfaceOf The WihoMachinSigbekaleIs PipadasẹhinShoveled

Agbegbe olubasọrọ rẹ jẹ diẹ sii ju 90% lati rii daju pe deede jiometirika ti gbogbo ẹrọ

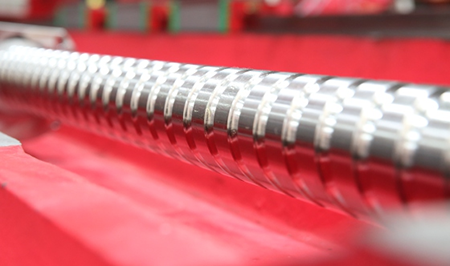

UltraStabiliAdeede

Awọn dabaru ọpá adopts awọn fifi sori mode tifixed pre-aifọkanbalẹ ni awọn opin mejeeji ati fifa ni awọn isẹpo simẹnti lati rii daju pe ultra-high ati ultra-stable konge ti ẹrọ ẹrọ labẹ irin-ajo nla.

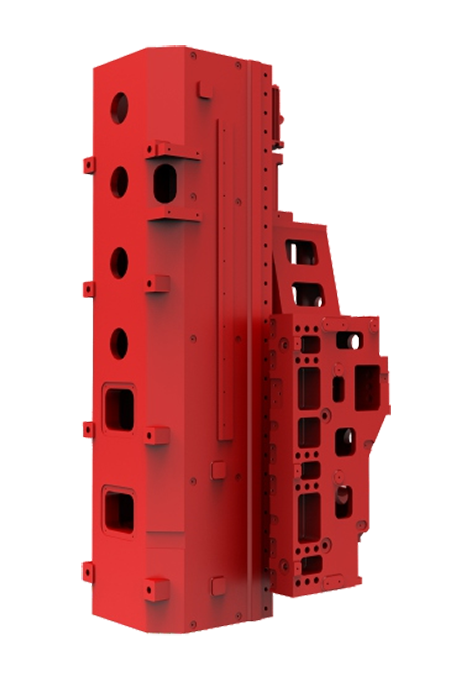

Ti ṣepọGantryAnd Base

Apẹrẹ iṣọpọ ọwọn, mu rigidity ti ẹrọ ati iduroṣinṣin processing.

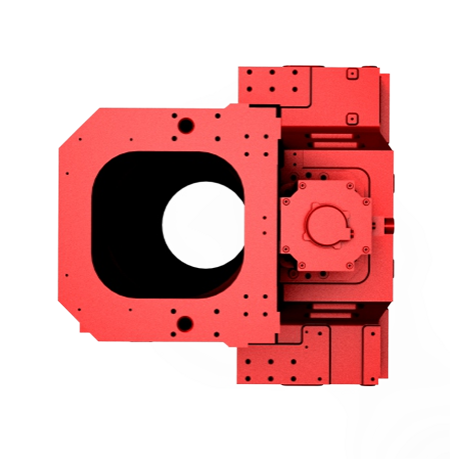

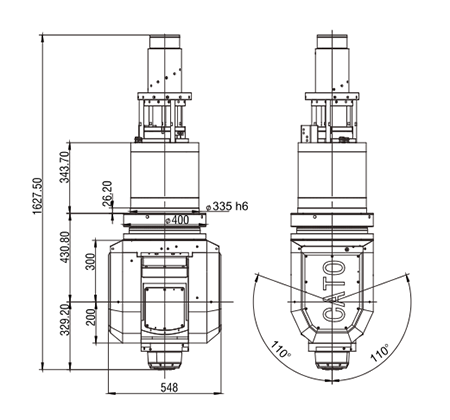

F1 orita Iru Amuṣiṣẹpọ Meji-ipo milling Head

Ẹya agbelebu asymmetrical ni lile igbekale ti o ga julọ ati idinku gbigbọn ju awọn awoṣe ipele kanna lọ.

Iwọn B / C nlo ọkọ ayọkẹlẹ awakọ taara ati eto idaduro hydraulic ti o ga julọ, eyiti o ni pipe ti o ga julọ, ifẹhinti odo ati yiya odo.

Apẹrẹ iyika ti omi tutu ati spindle ti ni ipese pẹlu iṣan omi aarin bi boṣewa, eyiti o le mu awọn iyipada iwọn otutu mu ni imunadoko ati rii daju pe konge giga.

Oiyan Iṣeto ni

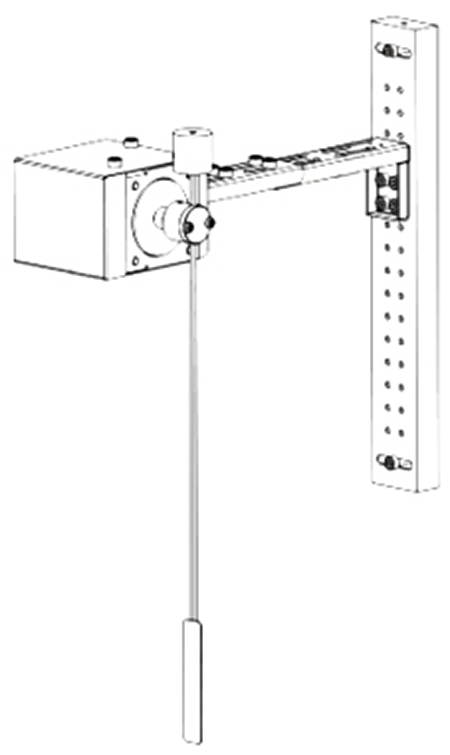

Iwari Ọpa Baje Ninu Iwe irohin naa

Ẹka wiwa ti fi sori ẹrọ ni ile-ikawe irinṣẹ, ati ilana wiwa ati ilana ilana ni a ṣe ni nigbakannaa, laisi ni ipa lilu processing.

Axialiyan Awọn iwọn

Ifihan agbara ti o wuwọn jẹ pulse oni-nọmba, eyiti o ni awọn abuda ti ibiti wiwa nla, deede wiwa giga ati iyara esi iyara.

Online erin System

Rmu eto irinṣẹ ṣiṣẹ ati akoko titete iṣẹ, ati ṣafipamọ akoko 90% iranlọwọ.

Rmu awọn ọja egbin ti o ṣẹlẹ nipasẹ aṣiṣe titete ti eto irinṣẹ ati iṣẹ-ṣiṣe, ati ilọsiwaju ikore.

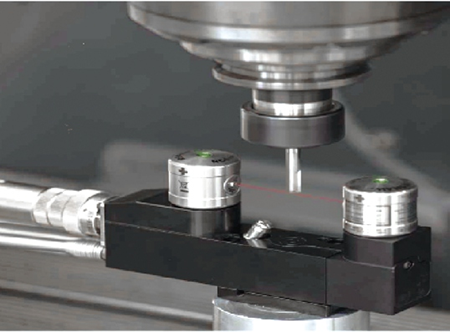

Ohun elo Ṣiṣeto Ọpa Lesa

Wiwa iyara ati deede ti iwọn ọpa lati rii daju lilo igba pipẹ laisi wọ

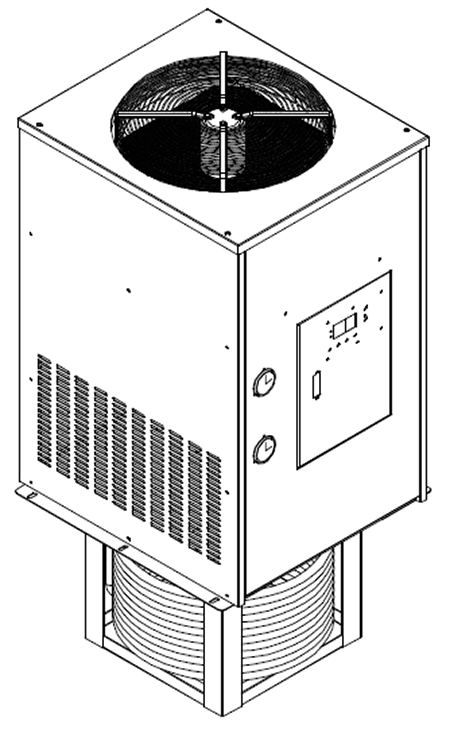

Ẹrọ Itutu Omi Gige

Iyipo gbigbona ti fifixture ati iṣẹ-ṣiṣe ti o ṣẹlẹ nipasẹ iwọn otutu ti dide ti gige FLfluid yoo ni ipa lori iṣedede ẹrọ.

Awọn eto le rii daju awọn iwọn otutu jinde ti gige fluid laarin 3-5 ℃

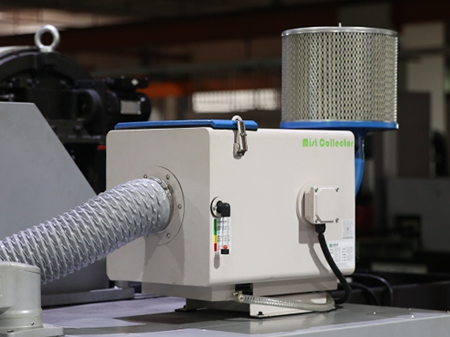

Epo owusu apejo System

Oṣuwọn puri cation ti o ga, iṣẹ iduroṣinṣin, ariwo ipalọlọ oor.Efe ni lter awọn omi-tiotuka air ati epo owusu èéfín ninu awọn onifioroweoro ati ki o jinna ìwẹnu awọn air.

Imọ ni pato

| Ise agbese | GF2020-5X | GF3020-5X | GF4020-5X | |

| Irin-ajo | X/Y/Z irin ajo aksi | 2000×2000×800mm | 3000×2000×800mm | 4000×3000×1000mm |

| Spindle imu to tabili aarin | 90-890mm | 80-880mm | -100-900mm | |

| Tabili | Iwọn tabili | 2000× 1100mm | 3000× 1200mm | 4000×2000mm |

| Max.tabili fifuye | 2000Kg | 2500kg | 20000kg | |

| Spindle | Spindle taper | HSK-A63 | HSK-A63 | HSK-A100 |

| Max.spindle iyara | 18000rmp | 18000rmp | 8000rmp | |

| Spindle motor agbara | 30/33.5KW | 30/33.5KW | 70/75KW | |

| Spindle motor iyipo | 72/85Nm | 72/85Nm | 350/450Nm | |

| Iwọn ifunni | Iyara iyara ti ipo X/Y/Z | 36/30/30 | 30/30/30 | 15/15/10 |

| Ige kikọ sii | 1-12000 | 1-12000 | 1-10000 | |

| ATC | Nọmba ti ọpa | 24T | 24T | 24T |

| O pọju ọpa ipari | 400mm | 400mm | 400mm | |

| O pọju ọpa opin | 120mm | 120mm | 250mm | |

| O pọju ọpa àdánù | 8kg | 8kg | 15kg | |

| Akoko iyipada irinṣẹ (irinṣẹ si irinṣẹ) | 4.5S | 4.5S | 5S | |

| Opo mẹta | Itọsọna ila-X | 45/4 rola | 45/5 rola | 45/4 rola |

| Y-axis itọsọna | 55/2 rola | 55/2 rola | 65 Roller | |

| Itọsọna Z-apa | 55/3 rola | 55/3 rola | 65 Roller | |

| skru X-apa | φ50×16 | φ63×16 | φ80×20 | |

| Y-apakan dabaru | φ50×16 | φ50×16 | φ63×16 | |

| Z-apakan dabaru | φ50×12 | φ50×12 | φ63×16 | |

| Itọkasi | Ipo ti konge | ± 0.005 / 300mm | ± 0.005 / 300mm | ± 0.005 / 300mm |

| Ntun ipo konge | ± 0.003 / 300mm ± 0.003 / 300mm | ± 0.003 / 300mm | ||

| Agbara | Ibeere agbara | Ipele-mẹta 380V± 10%,50Hz±1% Ipele mẹta 380V±10%,50Hz±1% | Ipele-mẹta 380V± 10%,50Hz±1% | |

| Afẹfẹ titẹ | ≥6kg/c ≥6kg/c | ≥6kg/c | ||

| Oṣuwọn afẹfẹ | ≥0.5mm³/min ≥0.5mm³/min | ≥0.5mm³/min | ||

| Iwọn ẹrọ | Iwọn ẹrọ | 20T 22T | 50T | |

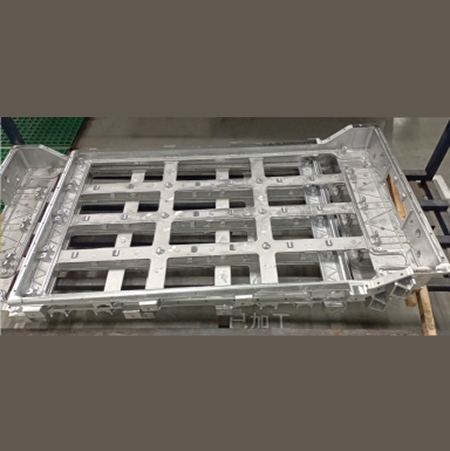

Awọn ọran Ṣiṣe

1.Ọkọ ayọkẹlẹMould

GaProcessingEṣiṣe

Ọkan-akoko clamping ti workpiece, 5-axis igbakana Iṣakoso

Inaro, petele ati ọpọlọpọ sisẹ igun ọfẹ le pari ni iṣiṣẹpọ

GaMerialiRimukuroRjẹun

Iyara giga, spindle agbara giga

Rigidity giga ati awọn abuda agbara giga ti gbogbo eto ẹrọ

GaCsisọFedRjẹun

XYZ axis wakọ iyara giga

Rigidity giga ati awọn abuda agbara giga ti gbogbo eto ẹrọ

2.OfurufuSigbekalePiṣẹ ọna

O tayọSurfaceProcessingQiwulo

Marun-axis igbakana Ige ohun elo

Ga-konge processing agbara

PupọShortenProcessingAnd PolishingTime

Awakọ mọto laini

X/Y/Z axis ga-iyara wakọ

GaPipadasẹhin

Iyara-giga, spindle agbara-giga

Rigiditi giga ati iduroṣinṣin giga ti gbogbo eto ẹrọ