Marun-ipo inaro machining aarin TK jara

Awọn ẹya ara ẹrọ

1.Excellent processing ipa

Ibusun simẹnti apapọ + gbigbe tan ina Y axis + jojolo rigidity giga jẹ iran tuntun ti awọn irinṣẹ ẹrọ-apa marun-giga giga. Ọpa ẹrọ CNC marun-axis ṣe aṣeyọri iṣẹ ṣiṣe milling ti o pọju, iṣẹ ṣiṣe ti o ga julọ ati pipe to gaju, lakoko ti o jẹ lile pupọ ati iduroṣinṣin. Iru iṣẹ agbara bẹẹ wa lati ara iduroṣinṣin giga rẹ ati itupalẹ FEM ti oye.

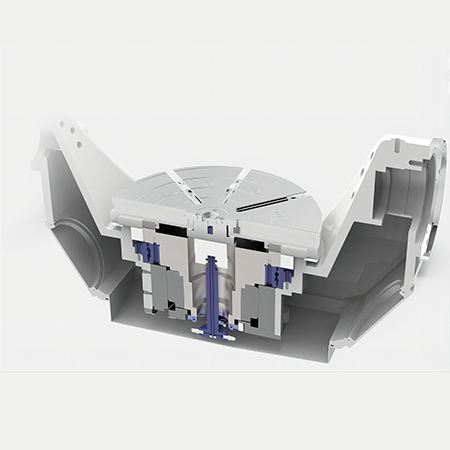

2.High rigdity ati išedede

3.High ìmúdàgba išẹ

4.Unparalleled iduroṣinṣin ati ilọsiwaju deede

Ibusun simẹnti gbogbogbo ni iduroṣinṣin ti ko lẹgbẹ; awọn gbigbe tan ina Y-axis + ga-rigidity jojolo mu ki awọn ẹrọ ni extraordinary gige rigidity; iwuwo awọn ẹya gbigbe ti fuselage ti wa ni iṣapeye lati ṣaṣeyọri iṣẹ ṣiṣe ti o ga julọ.

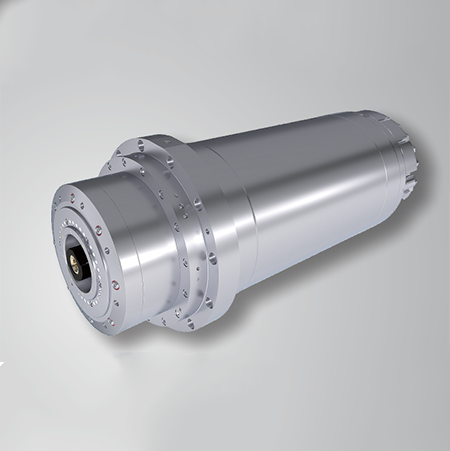

5.Independently ni idagbasoke spindle composite, ga ṣiṣe ati ki o rọrun isẹ

6.CNC imọ-ẹrọ idagbasoke oye

Awọn ọdun ti ile-iṣẹ ojoriro ohun elo axis marun-axis ni iṣakoso ominira ti awọn mechatronics, ṣiṣe awọn irinṣẹ ẹrọ diẹ sii iduroṣinṣin ati idagbasoke awọn iṣẹ idari ile-iṣẹ

7.Milling / turning ni idapo imọ-ẹrọ processing ṣe aṣeyọri pipe

Ṣiṣe ẹrọ pipe lori ohun elo ẹrọ ẹyọkan, pẹlu milling ati titan, pẹlu didi kan nikan ti o nilo, ni ipese pẹlu imọ-ẹrọ awakọ taara, ati iyara ti o pọju ti 2000rpm / min. Iyara sisẹ jẹ iyara ati idiyele eekaderi jẹ kekere, eyiti o jẹ nitori aini akoko iranlọwọ ati awọn iṣẹ afikun, ti o fa abajade ni awọn idiyele iṣelọpọ nkan ẹyọkan kekere ati deede processing giga.

Imọ ni pato

| Nkan | TK10 | |

| Awọn paramita sxis laini | X/Y/Z-axis ajoibiti (mm) | 130/100/130 |

|

| X/Y/Z oju-iweibi ijoko ti o yẹ (mm) | 0.008 |

|

| X/Y/ZrEpeat ipo deede (mm) | 0.005 |

|

| X/Y/Z-aksi iyara ipalọ ni iyara (m/min) | 15 |

|

| Iyara gige ti o pọju X/Y/Z-axis (m/min) | 10 |

| Awọn parametes axis Rotari | B-axis ajo ibiti o | +20°-125° |

|

| C-axis ajo ibiti o | n×360° |

|

| B/Cišedede ipo | 8'' |

|

| B/Crepeated ipo acamojuto | 5'' |

|

| BIyara ipalọpa iyara (rpm/min) | 50 |

|

| CIyara ipalọpa iyara (rpm/min) | 100 |

| Awọn paramita ẹrọ | Giga irinṣẹ ẹrọ (mm) | 2000 |

|

| Àtẹ̀sẹ̀ (mm) | 1000*1200 |

|

| Nẹtiwọọki ẹrọ (T) | 0.9T |

| Worktable sile | Iwọn tabili iṣẹ (mm) | Ø100 |

|

| O pọju.Iwọn iṣẹ-ṣiṣe (mm) | Ø100*100 |

|

| O pọju.iwuwo iṣẹ-ṣiṣe (kg) | 10 |

|

| Oju ipari Spindle si ijinna tabili (mm) | 90-220 |

| Awọn paramita irohin irinṣẹ | Ọpa irohin agbara | 20 |

|

| Awọn akoko iyipada irinṣẹ TT | 3 |

|

| O pọju.tool ipari (mm) | 60 |

|

| O pọju.tool opin (mm) | Ø20 |

|

| O pọju.tiwuwo ool (kg) | 0.5 |

Imọ ni pato

| Nkan | TK35 | TK50 | TK65 | TK80 | |

| Awọn paramita sxis laini | Iwọn irin-ajo X/Y/Z-aksi (mm) | 380/420/365 | 520/520/460 | 650/620/520 | 800/800/550 |

| Ijoko konge ipo X/Y/Z (mm) | 0.004 | 0.004 | 0.005 | 0.005 | |

| X/Y/Z tun ṣe deede ipo ipo (mm) | 0.003 | 0.003 | 0.004 | 0.004 | |

| X/Y/Z-aṣisi iyara ipalọja iyara (m/min) | 30 | 30 | 30 | 30 | |

| X/Y/Z-ipo to pọju. Iyara gige (m/min) | 15 | 15 | 15 | 15 | |

| Awọn parametes axis Rotari | A-apa ajo ibiti o | ± 120° | ± 120° | ± 120° | ± 120° |

| C-axis ajo ibiti o | n×360° | n×360° | n×360° | n×360° | |

| A/C ipo išedede | 8 '' | 8 '' | 8 '' | 8 '' | |

| A/C tun ipo išedede | 5 '' | 5 '' | 5 '' | 5 '' | |

| Iyara ipalọpa iyara A-axis (rpm/min) | 50 | 30 | 30 | 30 | |

| Iyara ipalọ-ọna C-axis (rpm/min) | 100 | 80 | 100 | 50 | |

| Awọn paramita ẹrọ | Giga irinṣẹ ẹrọ (mm) | 2300 | 2800 | 3300 | 3060 |

| Àtẹ̀sẹ̀ (mm) | 1800*3200 | 3600*3220 | 2480*4390 | 4530*2630 | |

| Nẹtiwọọki ẹrọ (T) | 6 | 10 | 11 | 18.5 | |

| Worktable sile | Iwọn tabili iṣẹ (mm) | Ø350 | Ø500 | Ø500 | Ø700 |

| T-Iho | 6-M10 | 8-M16 | 8-M16 | 8-M18 | |

| Iwọn iṣẹ-ṣiṣe ti o pọju (mm) | Ø350*250 | Ø520*410 | Ø650*410 | Ø800*500 | |

| Ìwúwo Max.workpiece (kg) | 100 | 400 | 500 | 500 | |

| Oju ipari Spindle si ijinna tabili (mm) | 110-475 | 170-630 | 170-690 | 180-730 | |

| Awọn paramita irohin irinṣẹ | Ọpa irohin agbara | 24 | 24 | 24 | 24 |

| Awọn akoko iyipada irinṣẹ TT | 3 | 3 | 3 | 3 | |

| Ipari irinṣẹ to pọju(mm) | 200 | 320 | 320 | 320 | |

| O pọju. Iwọn ila opin ti awọn ipo ti o wa nitosi laisi awọn irinṣẹ (mm) | Ø110 | Ø140 | Ø140 | Ø140 | |

| O pọju. Iwọn ila opin ti awọn irinṣẹ gige ti o wa nitosi (mm) | Ø65 | Ø80 | Ø80 | Ø80 | |

| Ìwúwo ohun elo ti o pọju (kg) | 6 | 6 | 6 | 6 | |

Imọ ni pato

| Nkan | TK20 | TK1000 | |

| Awọn paramita sxis laini

| Iwọn irin-ajo X/Y/Z-aksi (mm) | 250/250/250 | 1100/1100/700 |

| Ijoko konge ipo X/Y/Z (mm) | 0.008 | 0.006 | |

| X/Y/Z tun ṣe deede ipo ipo (mm) | 0.005 | 0.005 | |

| X/Y/Z-aṣisi iyara ipalọja iyara (m/min) | 15 | 30 | |

| X/Y/Z-ipo to pọju. Iyara gige (m/min) | 10 | 15 | |

| Awọn parametes axis Rotari

| A-apa ajo ibiti o | ±125° | ± 120° |

| C-axis ajo ibiti o | n×360° | n×360° | |

| A/C ipo išedede | 8'' | 8 '' | |

| A/C tun ipo išedede | 5'' | 5 '' | |

| Iyara ipalọpa iyara A-axis (rpm/min) | 50 | 30 | |

| Iyara ipalọ-ọna C-axis (rpm/min) | 100 | 100 | |

| Awọn paramita ẹrọ

| Giga irinṣẹ ẹrọ (mm) | Ọdun 2010 | 4000 |

| Àtẹ̀sẹ̀ (mm) | 1750*1290 | 3200*4200 | |

| Nẹtiwọọki ẹrọ (T) | 2.3 | 25 | |

| Worktable sile

| Iwọn tabili iṣẹ (mm) | Ø200 | Ø800 |

| T-Iho |

| M18T iru taara Iho | |

| Iwọn iṣẹ-ṣiṣe ti o pọju (mm) | Ø200*200 | Ø1100*700 | |

| Ìwúwo Max.workpiece (kg) | 30 | 2500 | |

| Oju ipari Spindle si ijinna tabili (mm) | 60-310 |

| |

| Awọn paramita irohin irinṣẹ

| Ọpa irohin agbara | 16 | 40 |

| Awọn akoko iyipada irinṣẹ TT | 3 | 4 | |

| Ipari irinṣẹ to pọju(mm) | 125 | 450 | |

| Iwọn ila opin irin-iṣẹ ti o pọju (mm) | 40 | Ø200 | |

| Ìwúwo ohun elo ti o pọju (kg) | 1 | 20 | |

Apeere Ilana

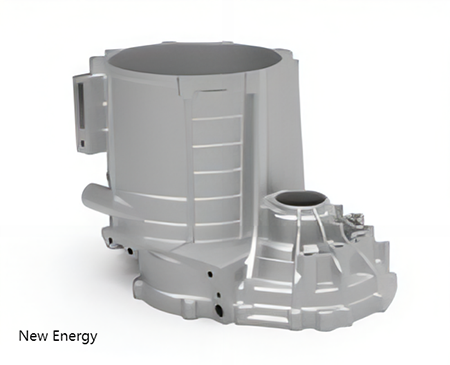

1.Agbara Tuntun

2.Awọn ohun elo iṣoogun

3.Ọkọ Industry

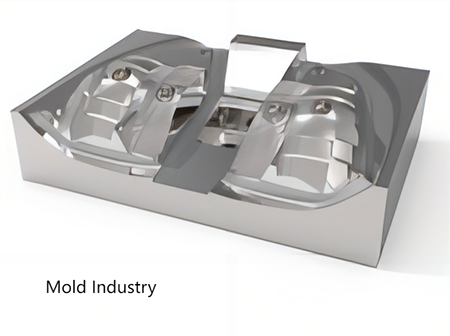

4.MúIile ise

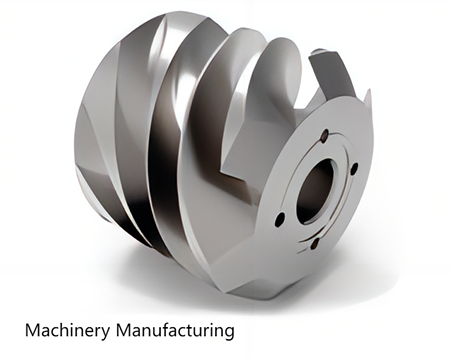

5.MachineryMiṣelọpọ

6.Ofurufu